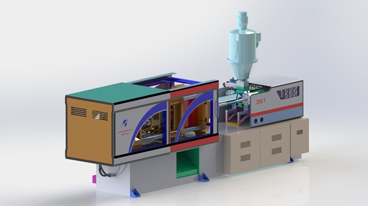

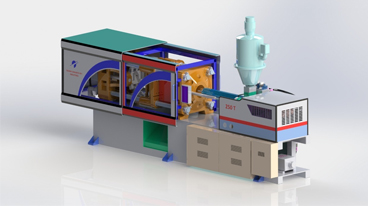

Swami Samarth offers Pet Line Injection Moulding Machine especially to

manufacture Moulded Pet Preform Products for Pet Bottles and Pet Containers

PET (Poly Ethylene Terephthalate) has recorded the fastest growth rate in the

Plastics Market and this is evident from the revolution witnessed in the fields of

mineral water, beverages, edible oil, detergents etc. where plastic bottles made

from PET are used Today, the food and beverages industry is increasingly using

PET to replace glass and other materials.

| Technical Specifications |

|---|

|

Item |

Unit |

110T PET |

130T PET |

150T PET |

180T PET |

Injection Unit |

Screw Diameter |

mm |

50 |

50 |

60 |

60 |

Screw L/D Ratio |

L/D |

24 |

24 |

24 |

24 |

|

Screw Stroke |

mm |

180 |

180 |

200 |

200 |

|

Screw Speed |

rpm |

190 |

190 |

190 |

190 |

|

Injection Weight PET |

gms |

450 |

460 |

471 |

801 |

|

Injection Rate |

cm3/sec |

176 |

252 |

252 |

405 |

|

Injection Pressure |

MPa |

127.6 |

127.6 |

127.6 |

122.4 |

|

Plasticising Rate |

gms/Sec |

37 |

42 |

55 |

85 |

|

Clamping Unit |

Clamping Force |

KN |

1100 |

1300 |

1500 |

1800 |

Clamping Stoke |

mm |

380 |

410 |

460 |

500 |

|

Space Between Tie Bar |

mm |

380/380 |

425x425 |

550x550 |

575x575 |

|

Max. Mould Height |

mm |

520 |

570 |

600 |

600 |

|

Min. Mould Height |

mm |

150 |

160 |

200 |

200 |

|

Max. Daylight |

mm |

900 |

1000 |

1060 |

1100 |

|

Platen Dimension |

mm |

600/600 |

625x625 |

780x780 |

810x810 |

|

Ejector Stroke |

mm |

120 |

150 |

175 |

175 |

|

Ejector Force |

ton |

5 |

5 |

8 |

8 |

|

No. Of ejector Pin |

|

5 |

5 |

5 |

7 |

|

Other |

Max. Pump Pressure |

MPa |

17.5 |

17.5 |

17.5 |

17.5 |

Electrical Motor |

kW |

22 |

30 |

30 |

37 |

|

Total Connected Load |

KW |

38.7 |

30 |

38.5 |

48.7 |

|

Oil tank Capacity |

L |

415 |

350 |

350 |

415 |

|

Machine Dimension |

m |

5.6x1.8x2.3 |

5.4.x1.52x2.03 |

6.1x1.8x2.5 |

6.3x1.8x2.5 |

|

Machine Weight |

Ton |

6 |

7 |

7.8 |

8 |

Item |

Unit |

230T PET |

280T PET |

350T PET |

450T PET |

|

Injection Unit |

Screw Diameter |

mm |

67 |

70 |

80 |

90 |

Screw L/D Ratio |

L/D |

24 |

24 |

24 |

24 |

|

Screw Stroke |

mm |

240 |

280 |

320 |

360 |

|

Screw Speed |

rpm |

160 |

135 |

110 |

94 |

|

Injection Weight PET |

gms |

1272 |

1272 |

2520 |

2702 |

|

Injection Rate |

cm3/sec |

475 |

519 |

639 |

558 |

|

Injection Pressure |

MPa |

122.4 |

122.2 |

121.8 |

121.2 |

|

Plasticising Rate |

gms/Sec |

62 |

100 |

120 |

160 |

|

Clamping Unit |

Clamping Force |

KN |

2300 |

2800 |

4500 |

|

Clamping Stoke |

mm |

550 |

650 |

720 |

850 |

|

Space Between Tie Bar |

mm |

660x660 |

710x710 |

810x810 |

875x875 |

|

Max. Mould Height |

mm |

710 |

750 |

800 |

820 |

|

Min. Mould Height |

mm |

200 |

250 |

300 |

350 |

|

Max. Daylight |

mm |

1260 |

1400 |

1390 |

1670 |

|

Platen Dimension |

mm |

920x920 |

990x990 |

1120x1120 |

1245x1245 |

|

Ejector Stroke |

mm |

160 |

200 |

250 |

250 |

|

Ejector Force |

ton |

11 |

11 |

15 |

15 |

|

No. Of ejector Pin |

|

9 |

13 |

13 |

13 |

|

Other |

Max. Pump Pressure |

MPa |

17.5 |

17.5 |

17.5 |

17.5 |

Electrical Motor |

kW |

45 |

45 |

55 |

55.5 |

|

Total Connected Load |

KW |

55.7 |

73 |

89.5 |

118.1 |

|

Oil tank Capacity |

L |

525 |

625 |

685 |

750 |

|

Machine Dimension |

m |

7.1x2.1x2.6 |

7.6x2.2x2.7 |

8.5x2.3x3.1 |

10.3x3.0x2.6 |

|

Machine Weight |

Ton |

10 |

13 |

18 |

26 |