We are leading 20 liter jar blowing machine supplier in India.A 20-liter jar blowing machine is an industrial equipment used in the manufacturing of large plastic containers or jars with a capacity of 20 liters or approximately 5.28 gallons. These machines are commonly used in industries such as packaging, food and beverage, chemical, and pharmaceutical, where large containers are needed to store and transport various liquids or products.

Here are some key details and features of a typical 20-liter jar blowing machine:

Machine Type: The 20-liter jar blowing machine falls under the category of blow molding machines, specifically used for producing large plastic containers.Blow Molding Process: This machine uses the blow molding process to create hollow plastic containers. In the case of a 20-liter jar, it typically involves the extrusion of molten plastic into a parison (hollow tube) and then stretching and blowing air into the parison to expand it into the desired shape of the jar.

Production Capacity: The production capacity of these machines can vary, but they are generally designed to produce a high volume of containers quickly and efficiently.

Container Size: As the name suggests, these machines are specifically designed to produce 20-liter jars. However, some machines may have the capability to produce containers of various sizes.

Material Compatibility: These machines are compatible with a wide range of plastic materials, including HDPE (High-Density Polyethylene) and PET (Polyethylene Terephthalate), which are commonly used for making plastic jars.

Automation Level: Modern 20-liter jar blowing machines often come with varying degrees of automation. Fully automated machines can handle tasks such as mold changing, parison control, and quality inspection with minimal human intervention.

Mold Design: The machine typically uses molds that are designed to produce the specific shape and size of the 20-liter jar. Mold design is critical for achieving consistent and high-quality production.

Cooling System: Effective cooling systems are essential to ensure that the plastic containers cool and solidify properly after being blown into shape.

Quality Control: Quality control features may include systems for checking wall thickness, ensuring even distribution of material, and inspecting for defects.

Energy Efficiency: Many modern machines are designed to be energy-efficient to reduce operational costs.

Maintenance and Servicing: Regular maintenance and servicing are important to ensure the machine operates smoothly and efficiently.

When looking for a supplier for a 20 liter jar blowing machine in India, be sure to inquire about the specific features, customization options, and after-sales support that they offer. Additionally, consider factors such as pricing, delivery time, and the reputation of the supplier in the industry. It's also important to meet any safety and regulatory requirements applicable in your region when operating such machinery. This unique blow moulding machine can be used to manufacture 20 liter jars at the rate of 80 jars per hour. It is well-equipped with a mould compensation system and a unique mechanical lock. The auto-controlled air ventilation in the heating chamber enables successful heat penetration while minimizing the heat in the heating chamber.

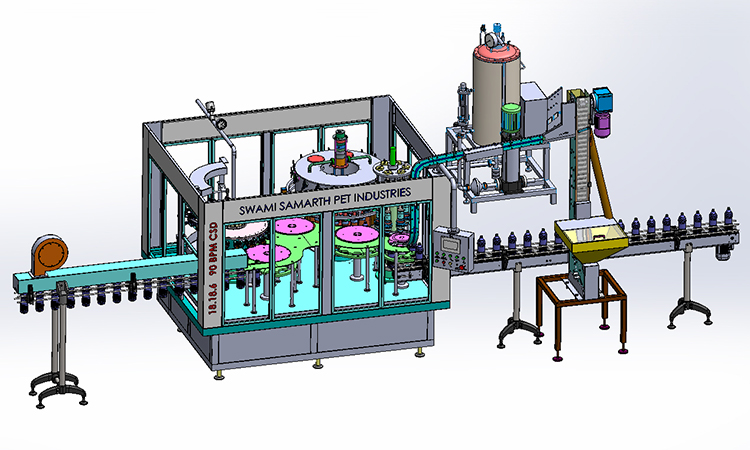

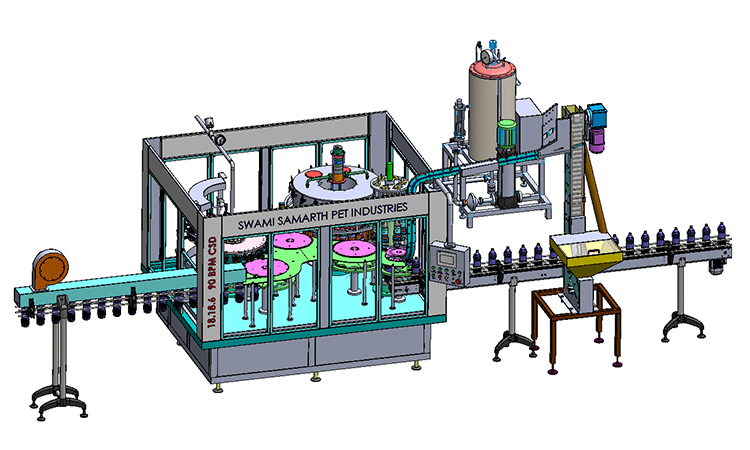

Swami Smarth Pet Industries is one of the leading for 20 liter jar blowing machine supplier in India.| Technical Specifications |

|---|

Technical Specifications |

||

No. of Washing Nozzles |

12 |

|

No. of Filling Valves |

12 |

|

No. of Capping Heads |

4 |

|

Length |

6.0 ft |

|

Width |

6.0 ft |

|

Height |

6.5 ft |

|

Main Drive Motor |

2.00HP |

|

Hopper Motor |

0.25 HP |

|

Air |

- |

|

Power Consumption |

5 KW |

|

Production |

3600BPH |

|

Technical Specifications |

||

No. of Washing Nozzles |

18 |

|

No. of Filling Valves |

18 |

|

No. of Capping Heads |

6 |

|

Length |

8.0ft |

|

Width |

6.0ft |

|

Height |

6.5 ft |

|

Main Drive Motor |

HP |

|

Hopper Motor |

HP |

|

Air |

- |

|

Power Consumption |

6 KW |

|

Production |

5400 BPH |

|

Technical Specifications |

||

No. of Washing Nozzles |

22 |

|

No. of Filling Valves |

22 |

|

No. of Capping Heads |

8 |

|

Length |

8.0 ft |

|

Width |

6.5 ft |

|

Height |

8.0 ft |

|

Main Drive Motor |

HP |

|

Hopper Motor |

HP |

|

Air |

||

Power Consumption |

4.849 KW |

|

Production |

7200 BPH |

|

Technical Specifications |

||

No. of Washing Nozzles |

24 |

|

No. of Filling Valves |

24 |

|

No. of Capping Heads |

8 |

|

Length |

13 ft |

|

Width |

12 ft |

|

Height |

6.5 ft |

|

Main Drive Motor |

HP |

|

Hopper Motor |

HP |

|

Air |

1.5 C.F.M AT 60 PSI |

|

Power Consumption |

10 HP |

|

Production |

9000 BPH |

|

Technical Specifications |

||

No. of Washing Nozzles |

40 |

|

No. of Filling Valves |

40 |

|

No. of Capping Heads |

10 |

|

Length |

15.0ft |

|

Width |

9.0 ft |

|

Height |

9.0 ft |

|

Main Drive Motor |

7.5HP |

|

Hopper Motor |

0.5H |

|

Air |

- |

|

Power Consumption |

8.952 KW |

|

Production |

15000 BPH |

|